Instructions for the previous version of the Pro-Gauge. The functionalities have stayed the same, only the components used changed.

With the Pro-Gauges controller you can connect a wide range of real gauges and control them through the USB port.

At the moment the list of supported instruments includes:

- Rev counter

- Electronic speedometer

- Fuel level gauge

- Water temperature gauge

- Fuel pressure (electronic, not mechanical) gauge

- Oil temperature gauge

- Oil pressure (electronic, not mechanical) gauge

- Turbo pressure (electronic, not mechanical) gauge

- Brakes' air pressure

Available connections

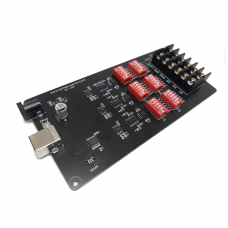

On one side of the board, you can find:

- The USB connector

- Power connector: connects the 12V power supply that was included with the board or that you supplied. If you are using your own power supply with a power jack that is not compatible with this connector, you can use the 12V and GND terminals on the other side of the board (see later).

On the opposite side of the board, you can find:

- 12V and GND connectors: this is where you connect the power wires from the gauges. the 12V terminal is always powered. Power wires from the gauge that are meant to be connected to the car's battery (always on) connect to the 12V terminal

- The 12V and GND terminalcan also be used to connect the external power supply, instead of the DC plug on the other side of the board. It is critical that you don't swap the positive and negative wires of the power supply, when you connect them to the 12V and GND terminals. The positive wire is usually red and connects to 12V. The negative wire is usually black and connects to GND.

- LGHT terminal. LGHT stands for "light". This terminal is powered with 12V only when SimDash is running and power is removed when SimDash is closed. Use it to switch the gauge's backlight on and off when the application starts and stops. Also connect to this terminal the gauge's wires that are meant to be connected to the car's ignition switch, that means the wires that are powered only when the key is rotated. If you prefer to use your own switch to control the gauge's backlight, use the 12V terminal instead for the backlight wires..

- The RPM and SPD terminals supply the signals for the tachometer and speedometer respectively.

- Terminals S1 to S6 are for the signals for the other gauges, like fuel indicator, water temperature and so on.

Configuring the rev counter

- Enable the Pro-Gauge output that will drives the rev counter, clicking the checkbox marked with 1 in the picture above.

- In the section marked with 5, set the maximum value of RPM for your specific rev counter.

- There are 21 sliders in the Rev Counter configuration screen.. Each slider has to be adjusted until the needle of the rev counter indicates the value displayed on the TEST button, between brackets). For example, in the picture above, the slider marked with 3 has to adjusted until the rev counter display the value 1.000 RPM. For fine tuning, the UP and DOWN arrows of the numeric textbox marked with 2 can be used.

Configuring the speedometer

The configuration section for the speedometer is in the picture above and is very similar to the one for the rev counter. Each slider has to be adjusted until the speedometer displays the speed value shown on the TEST button, at the right of the slider.

In the picture above for example, the slider marked with 3 must to be moved until speedometer displays the speed 30 Km/h.

The section marked with 5 indicates the speedometer's maximum speed value.

The signal wire from the speedometer connects to the controller’s terminal marked with SPD. The 12V and ground wires connect to the 12V and GND terminals of the Pro-Gauge.

Configuring the other gauges

The gauges indicating water and oil temperature, fuel level and pressure and oil pressure must be configured in the section displayed ain the picture above.

There are 5 sliders and each one has to be adjusted until the needle of the gauge moves to 0%, 25%, 50%, 75% and 100% of the range.

The section marked with 5 in the picture above is used to set what type of data is displayed by the gauge, the unit the data is displayed in and the minim and maximum values of the gauge.

For each of the S1…S6 connectors there is a DIP switch on the board that can be configured in 6 different allowed positions (see picture above for the allowed positions. Combinations not included in the picture are not useful).

POSITION 1 is the default position and should be tried first when adjusting the 5 sliders in the gauges configuration screen.

If any of the following situations happens:

- the needle of the gauge doesn’t move

- the needle of the gauge doesn’t reach the MIN or the MAX values of the gauge

- it is not possible to set the needle position accurately because to a small movement of the sliders in the configuration screen, corresponds a big movement of the needle

move the DIP switch from POSITION 1 to POSITION 2 and try to configure the gauge again. If the same happens again, move the jumper to the next position and so on until you have tried all 6 jumper positions.

The higher the DIP switch position is, the more accurately the needle can be positioned. For each small adjustment of the configuration screen's slider corresponds a finer change of the signal sent to the gauge.

So when you have to generate smaller signal changes, increase the position of the DIP switch. But because the number of steps the signal changes stays the same (same number of steps but smaller) the range covered will be smaller.

The signal adapter is introduced below and its function is to shift the range of the generated signal up and down, so that you can have a finely controlled signal (increasing the position of the DIP switch) but also have the signal to cover the range of values required by the gauge (operating the potentiometer of the signal adapter).

Signal adapter

The signal adapter should be used if the needle of the gauge doesn’t reach the MIN or the MAX positions of the gauges, when you move the sliders in the configuration screen.

Move the DIP switch corresponding to the gauge to a position where you are able to move the needle of the gauge, when you adjust the sliders in the configuration screen. It is ok if the needle doesn’t reach the MAX position of the gauge.Choose a position for the DIP switch as low as possible. So if both positions 1 and 2 make the needle move, prefer position 1. Move the needle to the maximum position you are able to. Don’t push the slider all the way to the right but stop when the needle can’t move any higher.

Connect the signal adapter to the gauge (see instructions below) and adjust the blue potentiometer using a screwdriver. The process is a bit trial and error but when you adjust the potentiometer at some point the needle of the gauge should start moving. Keep adjusting the potentiometer until the needle reaches the gauge’s MAX position.

Go back to the Pro-Gauge configuration screen and adjust the sliders. If now you are able to move the gauge’s needle all the way from the MIN to the MAX positions, you are done, otherwise you will have to keep playing with the potentiometer and possible with the position of the DIP switches on the Pro-Gauge.

The potentiometer of the signal adapter can be turned 15 times to the left or to the right. When you reach the start or the end positions the screw doesn’t block but you should be able to hear a click, from the potentiometer. That means you have turned it all the way, and keeping turning it doesn't produce any effect.

The signal adapter has 4 connections:

- - The GND terminal connect to the GND of the Pro-Gauge and the ground wire of the gauge (usually black)

- - The 12V terminal connects to the 12V terminal of the Pro-Gauge and the 12V wires of the gauge

- - The S terminal connects to one of the terminals S1…S6 of the Pro-Gauge

- - The G terminal connects to the gauge’s signal wire.

One signal adapter is included with the Pro-Gauge but more can be purchased separately if needed.

Please note: the Pro-Gauge is not officially compatible with full clusters removed from cars. Many are not compatible or no documentation is available on how to connect them to the Pro-Gauge board, so unfortunately we don't support them

Pro-Gauge

- Product Code: Pro-Gauge

-

£66.90

Available Options

Related Products

Signal Adapter

The signal adapter is a small board that is used to make the Pro-Gauge controller compatible with a ..

£3.50

80mm High Speed stepper motor Tachometer 11000 RPM

This tachometer offers extremely fast movements. The main features are:It uses high precision ..

£75.50

85mm Speedometer - Km/h

Fast moving gauge with amber or with backlight. Connecting the gauge to the Pro-Gauge controllerT..

£45.50

85mm Tachometer 4000 RPM

Fast moving gauge with white or amber backlight.Ideal for trucks simulators. Connecting the gau..

£47.90

85mm Speedometer - Mph

Fast moving gauge with amber or with backlight. Connecting the gauge to the Pro-Gauge controllerT..

£46.60